From circuit breakers to remote controls, your television to your smartphone, they all share a secret – they are potential treasure troves of valuable metals. One such metal, standing at the top echelon of this bounty, is silver. Though often overlooked due to the high-profile status of its golden counterpart, silver is a true superstar in the world of electronics. It conducts electricity better than any other metal and is used in a multitude of ways within our devices. Not only is silver irreplaceable in the electronics industry, but it’s also valuable to anyone who can reclaim it.

In this post, we’ll delve into the fascinating world of electronics, exploring the many places where silver might be hiding right under your nose. We’ll uncover the mysteries of silver use in various electronic components, and illuminate the process of how one might remove and recycle this precious resource. Whether you’re a tech enthusiast, an environmentalist aiming for more sustainable e-waste practices, or someone simply curious about where silver is found, join us on this journey to discover the unexpected places where this metallic treasure lies in wait. As we unravel this silver thread, prepare yourself for some illuminating revelations. Stay tuned, and let’s embark on this electrifying adventure together.

Places To Remove Silver From Electronics

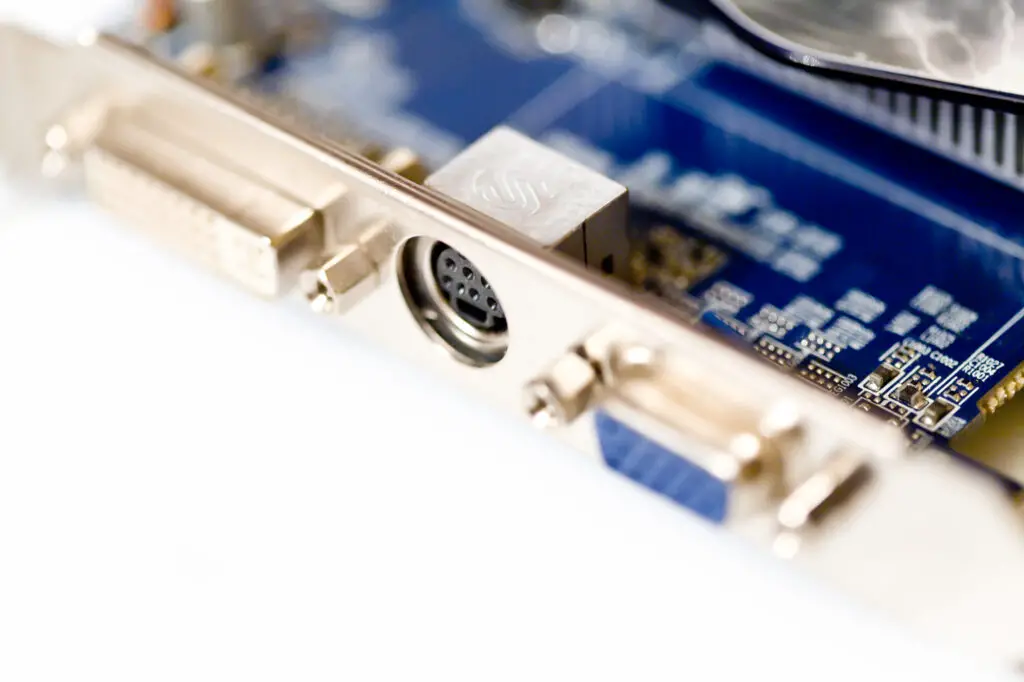

Circuit Board

Circuit boards, the beating hearts of our electronic devices, contain an assortment of valuable metals, silver being one of them. Silver’s superior electrical conductivity and resistance to corrosion makes it a crucial component in electronics manufacturing. Here are some common places where you can find silver in a circuit board:

Silver Ink and Conductive Pastes: One of the most common places to find silver on a circuit board is in the form of silver ink or conductive pastes. Manufacturers often use these materials to form conductive traces, which are the pathways that enable electricity to flow across the board. These silver traces are usually found on flexible printed circuit boards used in devices like keyboards, calculators, and smartphones.

Electroplating: Silver is often used as a surface finish on circuit boards, applied to the copper traces via a process known as electroplating. Silver electroplating provides an excellent conductive surface and protects the underlying copper from oxidation.

Through-Hole Technology: Older circuit boards that use through-hole technology might have silver in the solder that’s used to attach components to the board. It enhances the solder’s conductive properties and lowers its melting point.

Surface Mount Devices (SMDs): SMDs are tiny electronic components soldered onto the surface of a circuit board. Silver is found in the solder paste, which is used to bond the components to the board. It’s also sometimes used in the internal construction of some components, especially high-frequency ones.

Quartz Crystals: Silver is used to make the thin internal electrodes of quartz crystals, which are commonly used in devices like watches and telecommunication equipment to provide a stable clock signal.

RFID Tags: Some Radio Frequency Identification (RFID) tags use silver-based inks to create the antenna and circuitry. These are commonly found in security tags, contactless payment cards, and smart labels.

While it’s true that circuit boards contain silver, the amount is usually quite small. Large quantities of e-waste need to be processed to recover significant amounts of silver. However, with the right tools and knowledge, this silver can be extracted and recycled, reducing the environmental impact of e-waste and preserving a valuable resource.

Computer Chips

A computer chip, also known as an integrated circuit or microchip, is a complex ensemble of electronic components, including transistors, capacitors, and resistors. These are intricately organized on a semiconducting material, typically silicon, to perform various computational tasks. Silver, along with other precious metals like gold and palladium, is used in specific parts of a chip due to its excellent conductive properties.

Here are the primary places where silver can be found in a computer chip:

Silver Epoxy: Silver epoxy, a type of adhesive that includes silver particles to enhance conductivity, is often used to bond chip components together. This substance ensures strong physical bonds while maintaining electrical pathways.

Wire Bonds: In some chip manufacturing processes, tiny wires made of silver are used to connect the chip’s internal structures to the external pins that interface with the rest of the device. However, this role is often performed by gold due to its superior resistance to oxidation.

Heat Sinks: Heat sinks are essential components that help to dissipate heat generated by computer chips, protecting them from overheating. These can sometimes be coated with silver due to the metal’s high thermal conductivity, although aluminum and copper are more common.

RFID Chips: Silver is a key ingredient in certain types of RFID chips. These chips contain a silver-based ink that forms the antenna and circuitry, allowing the chip to communicate via radio waves.

However, it’s important to note that the quantities of silver present in individual computer chips are incredibly small – we’re talking microscopic amounts. Extracting silver from a single chip wouldn’t be feasible; significant quantities of silver can only be recovered through the processing of large amounts of e-waste. This requires specialized equipment and knowledge to do safely and effectively.

Mobile Phone

Mobile phones are small marvels of technology, cramming a multitude of components into a sleek and compact design. Due to its superb electrical conductivity and thermal properties, silver is an indispensable metal used in several parts of a mobile phone. Here are some key areas where silver can be found:

Circuit Boards: The circuit boards, or printed circuit boards (PCBs), are the brains of any mobile phone, where most of the computational tasks are carried out. Silver is found in the solder material used for bonding electronic components to the board. Additionally, it’s often used in the conductive traces, which carry electrical signals across the board.

Keypad Membranes: Silver-based ink can be found in the membrane switches used in older cell phone models with physical keypads. The ink forms conductive tracks that carry the signal when a key is pressed.

RF Components: Radio Frequency (RF) components used for wireless communication often contain small amounts of silver. This includes the oscillators, filters, and amplifiers that enable your phone to communicate with cell towers and Wi-Fi networks.

Touchscreens: Modern smartphones with touch-sensitive screens sometimes use a transparent layer of silver nanowires or other silver-based conductive materials. This layer registers the user’s touch and translates it into a command the phone’s software can understand.

Connectors and Switches: Silver can be found in various connectors and switches due to its excellent conductivity and resistance to corrosion. This includes the charging port, headphone jack, and volume and power buttons.

Vibration Motors: The tiny motor that makes your phone vibrate may use silver contacts to help transfer electricity.

Battery: Silver oxide batteries, while not the most common, are sometimes used in mobile devices due to their high energy density.

Remember, though, the quantities of silver used in mobile phones are tiny—often just a few hundred milligrams. Recovering this silver is a complex process that requires processing large volumes of e-waste. Doing so can help reduce the environmental impact of electronic waste and contribute to more sustainable tech manufacturing processes.

Hard Drives

A hard drive is an essential component in computers and laptops, serving as the primary storage medium for all types of data. While hard drives are often thought of as repositories for valuable digital data, they also contain physical treasure: precious metals like silver. Here are the places where you’ll typically find silver in a hard drive:

Printed Circuit Boards (PCBs): The PCB is a green board located on the underside of the hard drive. It controls the functions of the drive and communicates with the rest of the computer system. Silver can be found in the solder used to mount components on the board and sometimes in the thin conductive traces.

Read/Write Head: The read/write head is a tiny component that hovers above the spinning magnetic platters to read or write data. It uses magnetism to encode or decode information on the platter. These heads are often manufactured with silver alloy tips due to silver’s high conductivity and durability.

Connectors: Silver can be used in the various connectors within a hard drive due to its excellent electrical conductivity and resistance to corrosion. These include the power connector and the SATA or IDE connector that interfaces with the computer’s motherboard.

Spindle Motor: This motor, located in the middle of the hard drive, spins the magnetic platters at high speeds. The electrical contacts for this motor may contain silver.

It’s important to note, however, that the quantity of silver present in a single hard drive is minuscule. Extracting and recycling silver from hard drives is a process that requires specialized tools and skills, and is usually only practical when performed on a large scale. Nonetheless, understanding where these precious metals are used in our everyday electronics can promote more responsible recycling and waste management practices.

Keyboard Membranes

A keyboard membrane is an integral part of most modern keyboards, especially those found on laptops and low-profile desktop keyboards. These membranes replace the traditional mechanical switches with a much thinner and quieter solution. Silver plays a crucial role in these membranes, enabling the keyboard to register key presses reliably and effectively. Here’s where you can find silver in keyboard membranes:

Silver Conductive Traces: The membrane layers of a keyboard are printed with circuit patterns using silver-based conductive ink. When you press a key, it pushes the top membrane layer onto the bottom one, connecting these silver traces and completing a circuit. This sends a low-voltage signal to your computer, corresponding to the specific key you pressed. The computer interprets this signal and produces the appropriate character on the screen.

The silver-based ink is chosen for this purpose due to silver’s exceptional electrical conductivity, which ensures the keyboard responds accurately and quickly to each key press. It’s also resistant to corrosion, ensuring the keyboard’s longevity even with frequent use.

Despite its key role in keyboard function, the amount of silver in a keyboard membrane is extremely small—only a few milligrams at most. Extracting silver from keyboard membranes is not a trivial task and usually requires specialized equipment and a large volume of keyboards to make the process worthwhile. However, understanding the use of silver and other precious metals in our everyday devices highlights the importance of proper e-waste recycling to recover these valuable resources.

Ways Professionals Remove Silver From Electronics

Circuit Board

Removing silver from a circuit board involves a process known as e-waste recycling. It’s a complex, multi-step process that requires specialized equipment and safety precautions due to the presence of potentially toxic materials. Here’s a general overview of how it works:

Disassembly: The first step is to dismantle the electronic device and remove the circuit board. This might require a set of specialized screwdrivers or other tools.

Preparation: After you’ve obtained the circuit board, you’ll need to remove any non-metal components and coatings. This can often be achieved with a combination of mechanical processes (like shredding) and heat treatment.

Leaching: Once you’re left with just the metal components, you can begin the process of leaching. This involves soaking the materials in a solution that can dissolve the metals, known as a leachant. There are many different types of leachants, but a common one is a combined amount of nitric acid and hydrochloric acid . This step dissolves the silver along with other metals present.

Precipitation: After the leaching process, the solution contains dissolved metals. Precipitation involves adding another chemical to the solution that reacts specifically with the silver, causing it to form solid particles that settle at the bottom.

Collection: The silver particles can then be collected and melted down to form silver bullion. The other metals in the solution can also be recovered in a similar manner.

This is a generalized process and the specific steps and chemicals used can vary depending on the exact nature of the e-waste being recycled.

Important Note: Extracting silver from circuit boards involves dealing with potentially dangerous chemicals and materials. It should only be performed by trained professionals in a controlled, environmentally compliant facility. It’s also illegal in many places to attempt this kind of extraction at home due to the potential for environmental contamination and personal injury. Always recycle your e-waste responsibly by bringing it to a certified recycling facility.

Computer Chip

Extracting silver from a computer chip is a complex process that involves a few different stages. It requires specialized knowledge and tools, and it must be done in a controlled environment due to the presence of potentially toxic materials. Here’s a simplified version of the process:

Preparation: This step involves separating the chip from the rest of the device. You’ll need to carefully remove the chip from the circuit board it’s attached to.

Grinding: The chips are often ground into a powder to increase the surface area for the next steps. This process typically involves specialized machinery.

Leaching: The ground chips are then soaked in a leachant—a solution designed to dissolve the metals. This often contains chemicals known as aqua regia, which can dissolve silver and other metals.

Precipitation: After the leaching process, you’re left with a solution that contains dissolved silver and other metals. Another chemical is added that reacts specifically with silver, causing it to precipitate out as solid particles.

Collection and Purification: The solid silver particles can be collected, then further refined and purified through processes such as electrolysis, resulting in pure silver.

Important Note: It’s crucial to understand that this process should not be attempted at home or without the proper training, equipment, and safety measures. The chemicals used are hazardous and can cause serious injury or environmental damage if not handled correctly. In many places, it’s also illegal to attempt to extract metals from electronic waste without the proper permits due to these risks. Always bring your electronic waste to a certified recycling center where it can be processed safely and responsibly.

Mobile Phone

Extracting silver from a mobile phone, like from other electronics, involves a process known as urban mining or e-waste recycling. It’s a complex process that requires knowledge, special tools, and safety measures because of the potential presence of hazardous materials. Here’s a simplified outline of how the process might work:

Disassembly: The first step is to dismantle the mobile phone to get access to the circuit board and other components that contain silver. This might require a set of specialized screwdrivers or other tools.

Size Reduction: Once the circuit board is isolated, it often undergoes a process known as size reduction. This involves shredding or grinding the board to increase the surface area for the subsequent steps.

Leaching: The ground boards are then put through a leaching process. This usually involves soaking the materials in a leachant, a solution capable of dissolving the metals, such as nitric acid and hydrochloric acid (known as aqua regia).

Precipitation: After leaching, the solution contains the dissolved silver along with other metals. Precipitation involves adding another chemical to the solution that reacts specifically with the silver, causing it to form solid particles that settle at the bottom.

Collection: The silver particles can then be collected, melted down, and further purified to recover pure silver.

This is a broad overview, and the specifics can vary depending on the exact methods used.

Important Note: It’s essential to note that this process should only be carried out by professionals in a controlled and environmentally compliant facility. The chemicals involved are hazardous and can pose a risk to health and safety if mishandled. Also, improper disposal can lead to environmental pollution. Therefore, in many jurisdictions, it’s illegal to attempt this kind of extraction at home. Always recycle your e-waste responsibly by taking it to a certified recycling facility.

Hard Drive

Extracting silver from a hard drive involves a series of complex procedures and involves the use of potentially hazardous chemicals. This is why such a process should only be performed in a controlled industrial environment with the proper safety measures in place. Here’s a generalized outline of the process:

Disassembly: Hard drives must first be disassembled, which involves removing the outer casing to expose the internal components, including the disk platters, read/write head, and printed circuit board.

Size Reduction: After disassembly, the components that contain silver (primarily the circuit board) are often shredded or ground into a fine powder to maximize surface area and efficiency in subsequent steps.

Leaching: The ground material then undergoes a process known as leaching, in which it’s soaked in a chemical solution capable of dissolving the metals. This often involves an acid mixture, such as nitric acid and hydrochloric acid (known as aqua regia), capable of dissolving silver and other precious metals.

Precipitation: After the leaching process, the resulting solution contains dissolved metals. A separate chemical is added to the solution that reacts specifically with the silver, causing it to precipitate, or form solid particles.

Collection and Refinement: The precipitated silver particles can be collected from the solution, then further refined and purified through processes such as smelting and electrolysis.

Important Note: Due to the hazardous nature of the chemicals involved and the potential for harm to the environment and personal safety, it’s crucial not to attempt this process without professional knowledge and equipment. It’s also illegal in many places to try this kind of extraction without the proper licensing due to these risks. Always recycle your e-waste responsibly by taking it to a certified recycling center or facility.